In the life of almost every pump installation, there comes a time when the pump needs to be replaced. This may be because of age, failures, or the station’s needs outgrowing the pump’s capabilities. Dry-run submersible wastewater pumps are a flexible solution that can replace several other pump types and provide benefits to the user that other pump types cannot. This article will review wastewater applications and how dry-run submersible pumps can replace other dry-run submersibles, true submersible pumps, and dry pit pumps, often with minimal upgrades to the station.

A dry-run submersible wastewater pump utilizes a motor capable of operating submerged or completely dry. These motors can be used with a variety of wet ends—standard solids handling pumps, chopper pumps, screw impeller pumps, and grinder pumps, among others. To operate dry, the motor needs to have appropriate cooling. Usually in the form of a cooling jacket, circulating liquid moves the heat away from the motor.

What is the difference between Submersible and Dry-run Submersible Pumps?

Submersible pumps are usually installed in a lift station containing anywhere from one to four pumps, and often on a rail system. They require a certain level of submergence for motor cooling. Based on the motor design and where the control levels are set, these can range from completely submerged to only partially submerged.

The key difference between a submersible and a dry-run submersible motor is the level of cooling required. Submersibles require partial or full submergence. A dry-run submersible can operate continuously with the motor fully unsubmerged. This allows the active volume of the station to be lowered. This small change may not seem beneficial. However, it creates extra space in the wet well, allowing for pump capacity upgrades.

For areas that are experiencing population growth, a motor size could be easily increased without changing much of the wet well aside from the pump and control panel. Note the pump discharge size would need to stay the same. Oftentimes the dry-run submersible can use the same rail system as the submersible.

Replacing Submersible Pumps

Furthermore, reducing the overall level in the lift station can also keep the wet well a bit cleaner. A constant challenge in wastewater is floating debris, which collects in the station and needs to be removed regularly. This is often done with a vacuum truck cleaning out the entire station, which is costly. Because dry-run submersibles can pump the level down closer to the volute, the pumps are more likely to capture some of the floating debris. This will increase the time between vacuum truck visits.

Both points need to be taken with a note of caution. First, local codes may dictate the control levels and storage volumes, and those take precedence over any other design choices. Second, when setting the “off” level in a station, it cannot be too far down the volute, and that increases the risk of air entering the volute and causing the pump to airlock.

What is the difference between Dry pit and Dry-run Submersible Pumps?

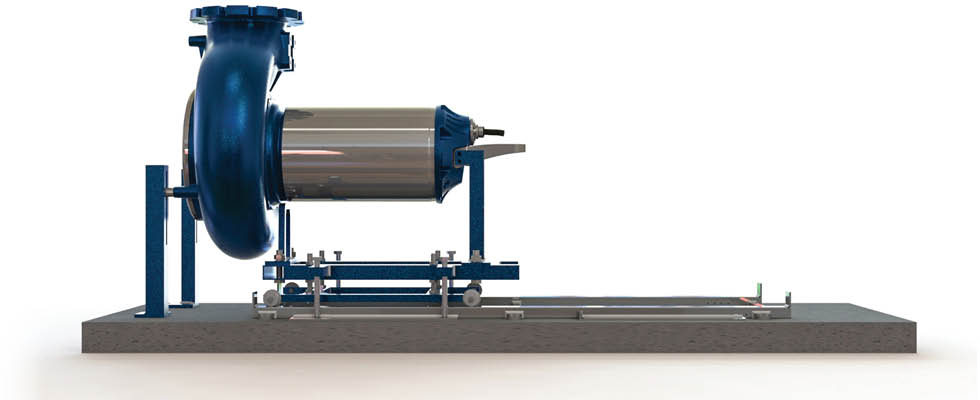

Dry pit pumps have more installation flexibility than submersible pumps in that they can be vertical or horizontal, close coupled or long coupled, or have extended shafts that allow the motor to be installed multiple levels above the pump itself. In this installation, a critical aspect is ensuring the pump remains above water. These pumps are dry pits. A common installation is a two-well system, where one is a holding well for the wastewater and the other is dry.

The pump is located in the dry well and a suction pipe connects the pump to the wet well. This keeps the pump dry while the wet portion operates similarly to a submersible pump station. Dry pit pumps are typically an end suction style. They tend to utilize open drip proof (ODP) or enclosed fan-cooled (TEFC) type motors and double mechanical seals. Oftentimes, the seal chamber needs a clean water flush. Adding complexity to the installation, this requires additional piping, a source of clean water, and a secondary pump to move the clean water.

Replacing Dry Pit Pumps

Since dry pit pumps cannot operate submerged, dry-run submersibles have an inherent advantage. Not only does this remove the need for the dual well system, but it protects the installation from potential flooding. Flooding can happen for many reasons, including weather-related and accidental. Incidents like force main breaks, valve failures, and heavy rains can all cause flooding in pump stations. Dry pit pumps can be damaged during flooding, whereas dry run submersible pumps will not only be undamaged but may even continue to operate, although this is dependent on how the station is designed and built.

The need for a clean water flush is also eliminated with a dry-run submersible. Because these pumps are designed to be submerged, the seal chamber is completely sealed from the exterior of the pump. The seals still need to be lubricated, but this is accomplished through the pumped fluid, the cooling jacket fluid, or other means. This can result in cost savings for the installation, a reduction in complexity, and less equipment to operate and maintain.

The article was first published in Pumps & Systems magazine in November 2023.